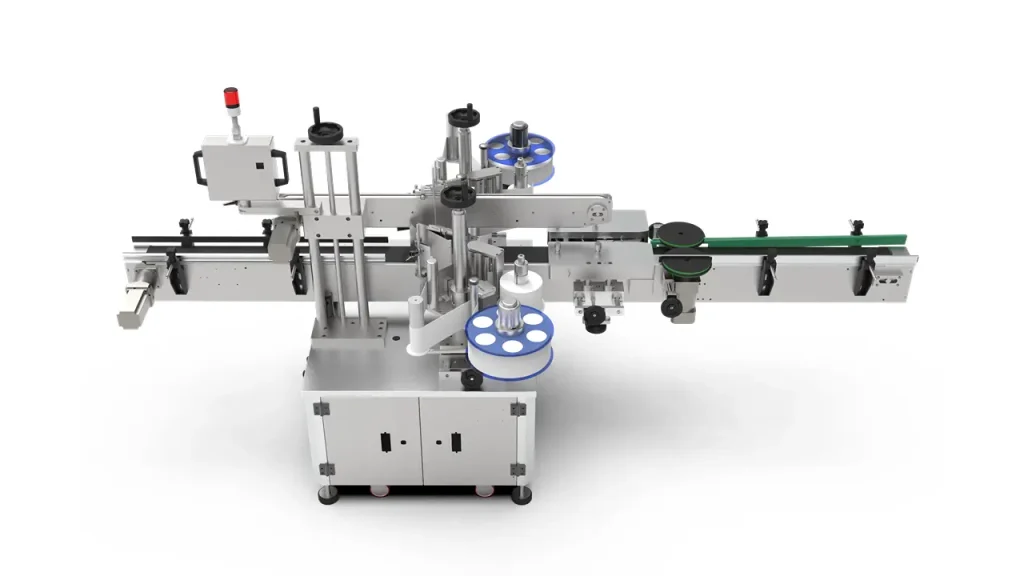

Double Side Bottle Labeling Machine

Double side bottle labeling machine is a kind of automation equipment used for square bottle, flat bottle double side labeling application, such as lubricating oil bottles, laundry detergent bottles, detergent bottles, milk bottles, shower gel bottles, shampoo bottles, and so on. It can also be applied to the side labeling of some cardboard boxes and cartons. It features high speed, high precision and good labeling effect.

The double-sided bottle labeling machine has two label applicators, each of which can be equipped with components such as date coding mechanism or printing engine. It can be flexibly adjusted according to the size and shape of the product to meet different packaging needs. It has a wide range of applications in food, daily chemical, pharmaceutical, cosmetic and other industries.

Double Side Bottle Labeling Machine

| Product Name | Automatic Double Side Labeling Machine |

| Model | GST-712 |

| Voltage | AC220V, 50Hz, single phase |

| Labeling accuracy | ±1mm |

| Labeling Speed | 10-200pcs/min (related to the label size and product size) |

| Applicable product height | Height 50mm-300mm, length 20-150mm, Width 20-120mm |

| Available Label Material | (Backing paper) width 10-150mm, length (winding direction) 15-300mm |

| Maximum label incoming size | Diameter 250mm, Inside diameter of paper roll 76mm |

| Gas consumption | Not need |

| Working Environment | 10-40℃ |

| Environmental temperature | 15-85% |

| Machine Dimension | About 3000±200(L) *1550±200 (W) *800±1450 (H)(mm) |

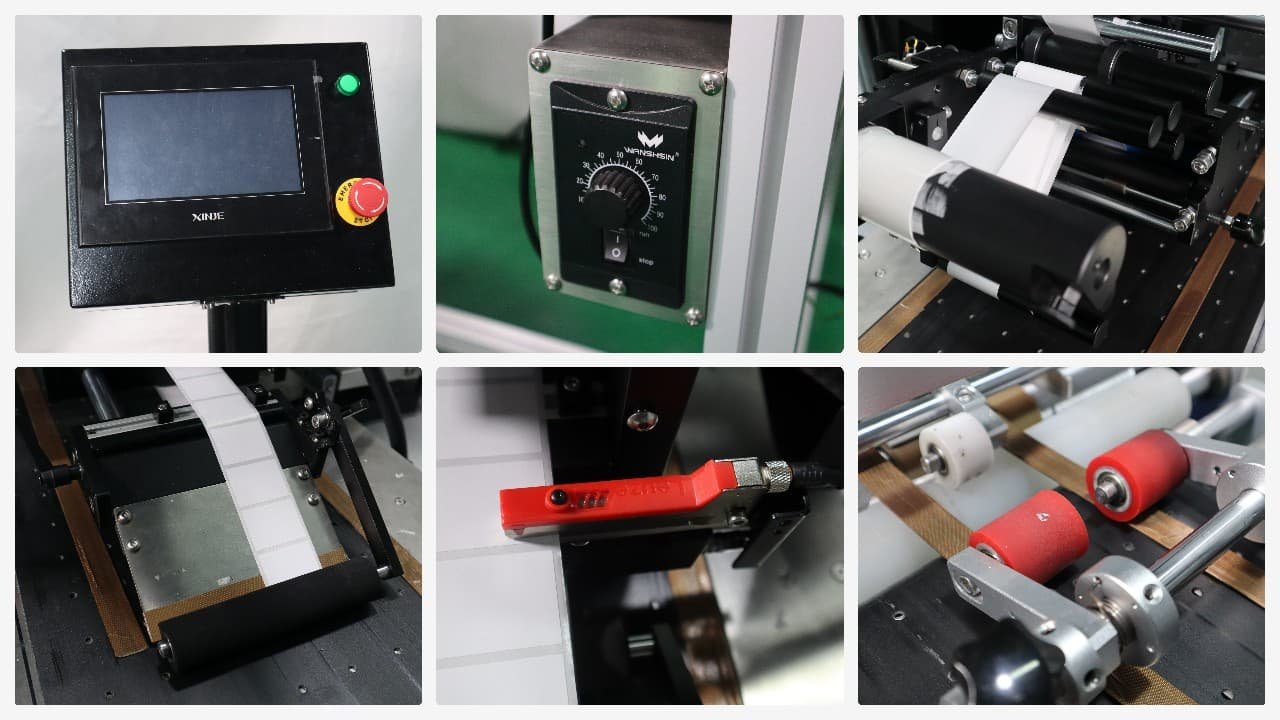

| No. | Item | Brand | Origin | QTY |

| 1 | Step motor for label station | Leadshine | China | 2 |

| 2 | Step motor drive for label station | Leadshine | China | 2 |

| 3 | Servo motor for conveyor | Xinje | China | 2 |

| 4 | Servo driver for conveyor | Xinje | China | 2 |

| 5 | Speed control motor for gapping roller | Wanshsin | China | 1 |

| 6 | Speed control motor for clamp chain | Wanshsin | China | 1 |

| 7 | Photoelectric sensors | Omron, Schneider | Japan/France | 1 |

| 8 | Leakage circuit breaker | Chint, Schneider | China/France | 1 |

| 9 | PLC | Mitsubishi | Japan | 1 |

| 10 | Aluminum alloy rack | Gosunm | China | 1 |

| 11 | Touch screen | WECON | China | 1 |

NOTE: the configuration may be adjusted reasonably according to the actual material delivery time, and the configuration can be revised according to customer needs

- High efficiency: Two sides can be labeled at the same time, increasing productivity.

- High precision: Each label applicator has its own positioning and application device, which can ensure that each label has the same position and angle.

- Wide application range: It can be adapted to packaging containers of different sizes, shapes and materials.

- High flexibility: The size, position and angle of the label can be flexibly adjusted to meet different packaging needs.

- Convenient maintenance: Adopting modularized design, easy maintenance and upkeep, simple operation.

- Intelligent control: Equipped with intelligent control system, it can monitor the labeling situation in real time and make timely adjustments when abnormalities are found.

- Environmental protection and energy saving: Adopting advanced energy saving technology, it can effectively reduce energy consumption.

- Humanized design: easy and convenient operation, equipped with touch screen and other humanized design, making the operation more convenient.

- High reliability: the use of high quality parts and materials to ensure the stability and reliability of the equipment.