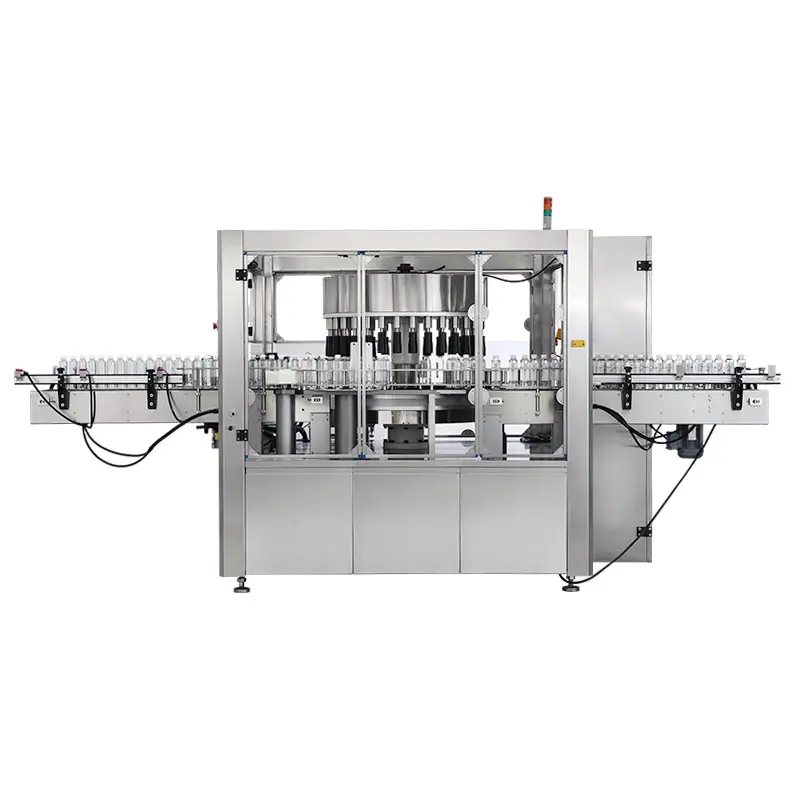

Rotary Labeling Machine

Rotary labeling machine is a kind of automation equipment applied for high-speed labeling of bottles.

High Speed Rotary labeling machine

Rotary labeling machine is a kind of high-speed automatic labeling equipment, which is driven by high performance servo motor and adopts rotary motion to realize labeling. The label is released from the label rewinding mechanism at a certain speed, and then the label is applied to the bottle by the label applicator to complete the labeling task.

Founded in 2007, Gosunm specializes in R&D, manufacturing, maintenance and service of labeling machines and packaging automation line equipment. We maintain long-term cooperation with many international famous enterprises, and our equipment is widely used in daily chemical, beverage, food, pharmaceutical and other industries.

The rotary labeling machine is a combination of Gosunm’s top technology and the latest research and development achievements, and the technology level is in the leading position in the same industry. Our high speed rotary labeling machine has the following advantages.

Gosunm rotary labeling machines are divided into adhesive series and hot melt series.

Rotary Adhesive Labeling Machine

Hot Melt Rotary Labeling Machine

Stable mechanical structure ensures labeling accuracy even at high speeds.

*Adopted the original patented design-independent center shaft, which ensures that the upper and lower turntable systems of the equipment always accurately correspond to each other, avoiding the positioning errors caused by the positioning columns in the traditional structure, and at the same time completely abandoning the unnecessary upper pressure turntable locking device, which makes the operation of the equipment more convenient and improves the use of efficiency.

*One-piece cylindrical aluminum alloy glue box is adopted to avoid the risk of the bottom of the glue box falling off under the long-term high-temperature operating environment.

*The one-piece rubber rollers, no assembly welding, avoiding the loss of precision caused by the lack of processing precision.

*Split labeling wheel, which can improve the accuracy of the equipment and help users save the cost of spare parts.

*Stainless steel one-piece cutter roller, high precision, long service life, stable label cutting, no need to change the cutter when changing labels.

*Adopting the company’s patented design of non-destructive bottle feeding system, which avoids the surface scratches caused by the rotating friction of the bottle feeding screw of the traditional equipment.

*Glue supply system integrated design, no hose, no reflux, so that the overall structure is more compact, improve the thermal efficiency of the system, reduce the cost of equipment. And the rubber roller adopts casting process, which avoids heat deformation of parts and ensures the operation precision.

*Adopt radial non-contact air distribution system to reduce the power of the equipment and facilitate the maintenance and repair of the equipment.

*Independent vacuum air supply system reduces the power of vacuum pump and lowers the system noise.

*The label applicator adopts gearless transmission, which improves the transmission efficiency of the system and reduces the power consumed by the motor, so that the economy of the equipment can be improved.