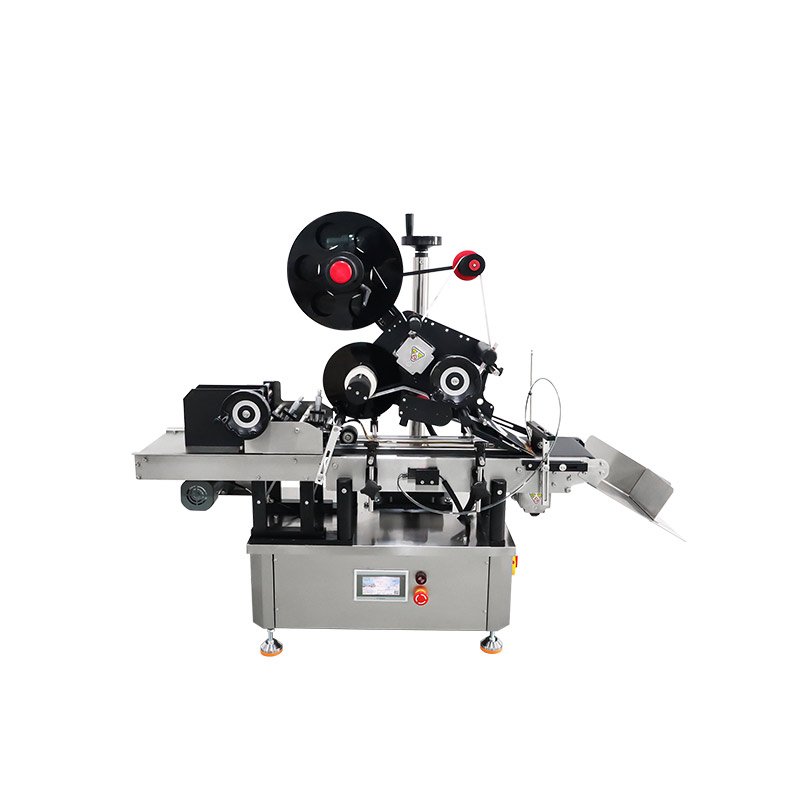

Box/Card/Bag Top (Bottom) Labeling Machine

Labeling on the top or bottom surface of an object is called flat labeling.

Usually, labeling in the upper or lower plane of regular or irregular objects can be collectively referred to as flat labeling. Below, we will introduce what a flat labeling machine is, what its applications are, and how to choose the right machine according to the number of labels, size, position, labeling method, labeling speed, and labeling application.

Gosunm has a team that can provide all kinds of ingenious engineering design, can be ready to help customers overcome all kinds of challenges, a wealth of experience and increasingly perfect technology makes Gosunm become the most popular manufacturers and experts in the industry. At our main factory in Dongguan, China, we have assembled market-leading labeling and packaging technology, and give more than reasonable advice from the user’s point of view, so that the user can feel the charm of Made in China.

According to the Labeling Position Classification

Top surface labeling, Top surface multi-label labeling, bottom labeling, top and bottom labeling.

Classification by Application

Boxes, bags, cases, cards, paperboard, PE bags, aluminum bags, bottle caps, square bottles, saline bags, egg cartons, fresh food boxes, etc.

Classification by Labeling Method

Roll labeling (the most common), suction labeling (the height of the labeled object adaptive), blowing labeling (without direct contact with the object)

Categorized by Label Printing

Pre-printed labels, labels with identical specifications.

Printing and labeling, according to different products to print different labels.

Classified by the Number of Labeling Applicator

Single labeling applicator, double labeling applicators, multiple labeling applicators. It can be flexibly matched according to the number of labels and labeling position, and is characterized by compact structure and high cost-effectiveness.

Classification by Labeling Speed

Normal, high speed, labeling speed adaptive.

Classification by Machine Size

Semi-atuo, Desktop, Vertical

How to Choose the Right Flat Surface Labeling Machine

With the above categorization, I believe you have a sufficient understanding of the division of flat labeling machine. How to choose the right machine?

- Determine what kind of product and product material? Is the box, bottle, cap, bag, card, etc., the product needs to be labeled, whether the plane is concave, raised or irregular edges. Is the product material paper, plastic, glass, ceramic or metal?

- Determine the size, quantity and material of the label.

- Determine the location of the label, whether it is on the top, bottom, sealing paste, etc.

- Determine the speed and accuracy of the labeling

Box/Card/Bag Top and Bottom Labeling Machine

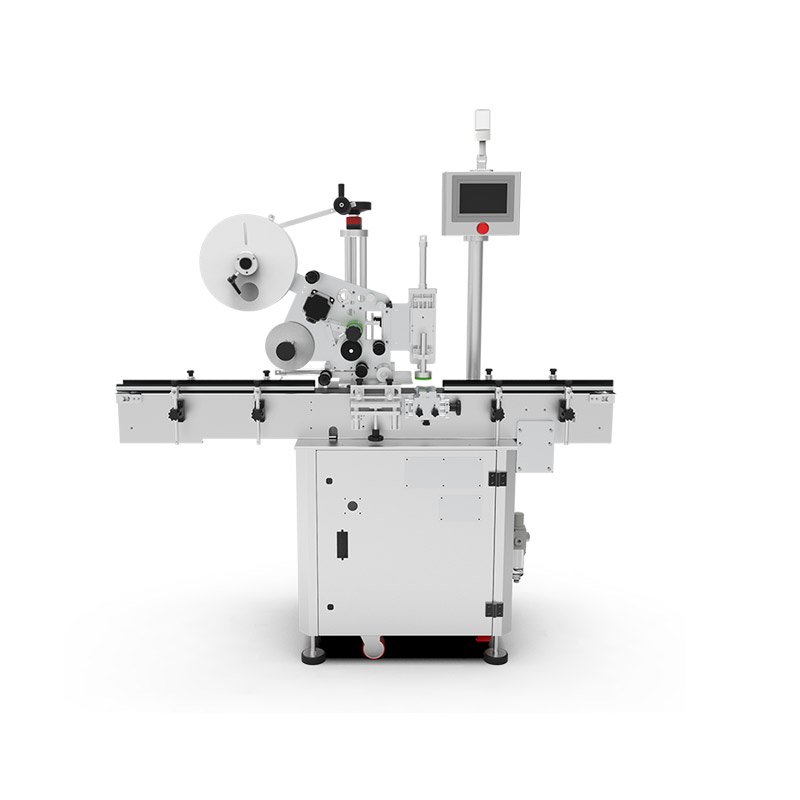

GST-113 Series - the most widely used for top surface labeling of various products

Top surface labeling machine, the most widely used of all surface labeling machine series. It can be used for top labeling of boxes, caps, square bottles, flat bottles, bags with products or any other products. For products with uniform specifications, roll-on labeling is commonly used; for products with non-statistical specifications, suction or blow-on labeling can be used. This series of machines is very easy to operate and has very high precision.

GST-115 Series - the best choice for top labeling of paper and card products

The pagination labeling machine, also called card labeling machine, is commonly used for top labeling of very thin products such as cards, paper, PE bags, aluminum foil bags and so on. The machine itself is equipped with a pagination mechanism, which can automatically separate the organized cards, papers and bags one by one onto the conveyor belt for automatic labeling. It greatly improves the labeling precision and labeling efficiency.

Top and Bottom Labeling Series--Simultaneously labeling Top and Bottom of products

In order not to affect the beauty of the product packaging, need to label the bottom of the product, GST-216 bottom labeling machine is a very good choice, in some fragile cookie boxes, bread boxes and other products we have a wide range of applications.

If you need to label the top and bottom of the product at the same time, GST-215 machine is the best choice. This machine is compact and can label both the top and bottom of the product at the same time. Usually most products can be run on a split belt, but for some small or unstable products we also have the perfect solution.

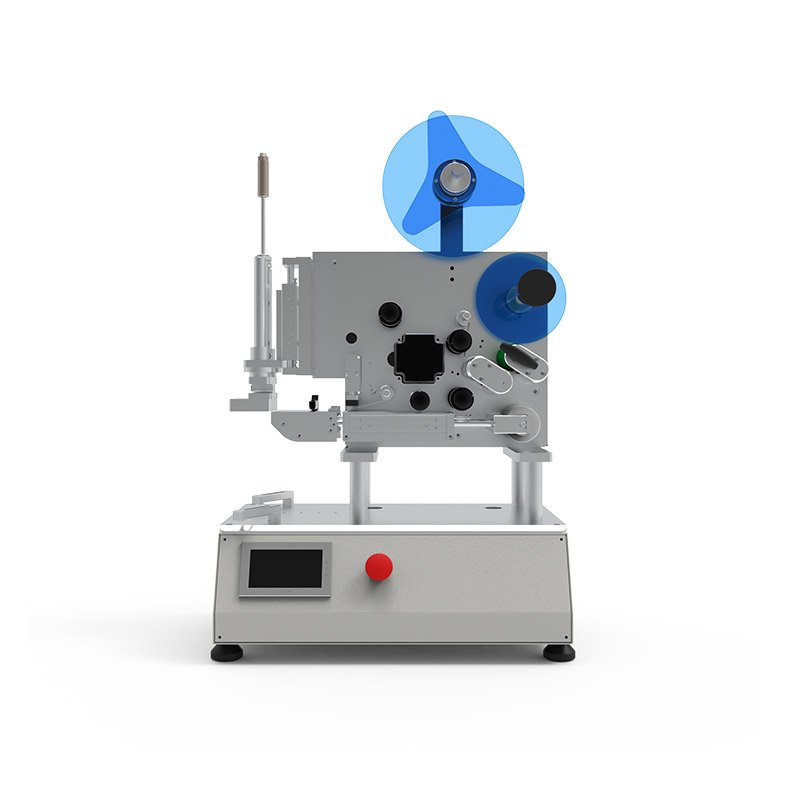

Semi-automatic Flat Labeling Machine Series - for flat labeling of irregular objects, with the advantage of high precision

Semi-automatic labeling machine is usually the most economical choice when facing some irregular objects or placing unstable objects for top labeling. According to our partners’ feedback, they occasionally have some irregular products need to be labeled, but the number of such products is not large, the automatic labeling machine cost is high, the frequency of use is low, and occupies a large area of the workshop, is not the ideal solution. After fully listening to our partners, Gosunm will customize some sets of small semi-automatic machines according to the customer’s products, which can be moved to the table and used individually.

-1.jpg)

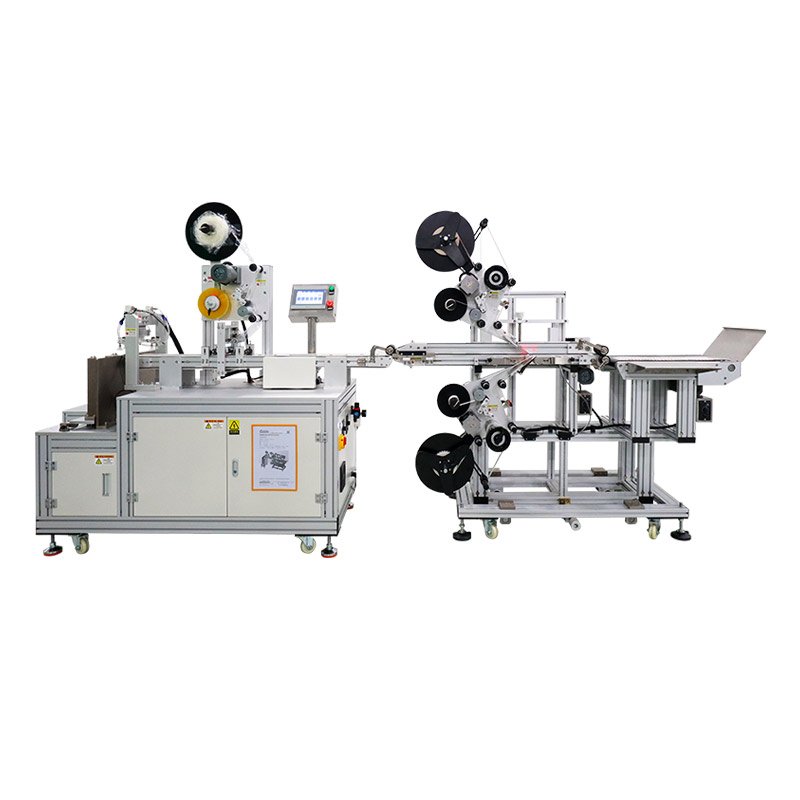

Label Applicator Series - Can be connected directly to the complete production line to complete the labeling operation

Often, adding labeling equipment to a complete production line requires dismantling and reorganizing the original production line and connecting a labeling machine at a suitable location. This method is time-consuming, labor-intensive, disrupts the original machine layout, and is prone to causing line failures.Gosunm GST-51 Series Label Applicator, without destroying the original production line, simply adjust the parameters of the machine, and directly carry the machine to the appropriate position on the conveyor belt, and then labeling can be carried out.

Plane Printing and Labeling Series - different products correspond to different labels, in the latter part of the product packaging has a wide range of applications.

Printing and labeling can be divided into real-time printing and cache printing. Simply put, each product is labeled with different labels is real-time printing, each batch of products with different labels is cache printing. In fresh food, express packaging, large e-commerce companies have a wide range of applications.

Cache printing can be connected to the computer, through the software will be edited labeling data sent to the printing device, after printing automatically labeling. The same batch of products apply consistent labeling, you can use cache printing, so that each labeling without fear of error.

Real-time printing of the label data content is real-time, can come from the database, scanning gun or DWS and other devices, the information obtained must be converted by the software, and then transmitted to the printing and labeling machine. Real-time printed labels have uniqueness, a product corresponds to a label, for example, in the courier shipment, a buyer’s courier information must correspond to the package attached to the A buyer.

Relatively speaking, the speed of cache printing and labeling is faster than real-time printing and labeling.

Customized Flat Labeling Machines - Providing solutions to meet all product flat labeling requirements

Gosunm has a professional R&D team ready to provide the best solutions for various user needs. For example, mobile phone protective film labeling, fruit labeling, mask labeling, RFID labeling and so on.

.jpg)

.jpg)

.jpg)

.jpg)

-编织袋.jpg)

.jpg)

上平面贴标头-运动手套-刘静.jpg)