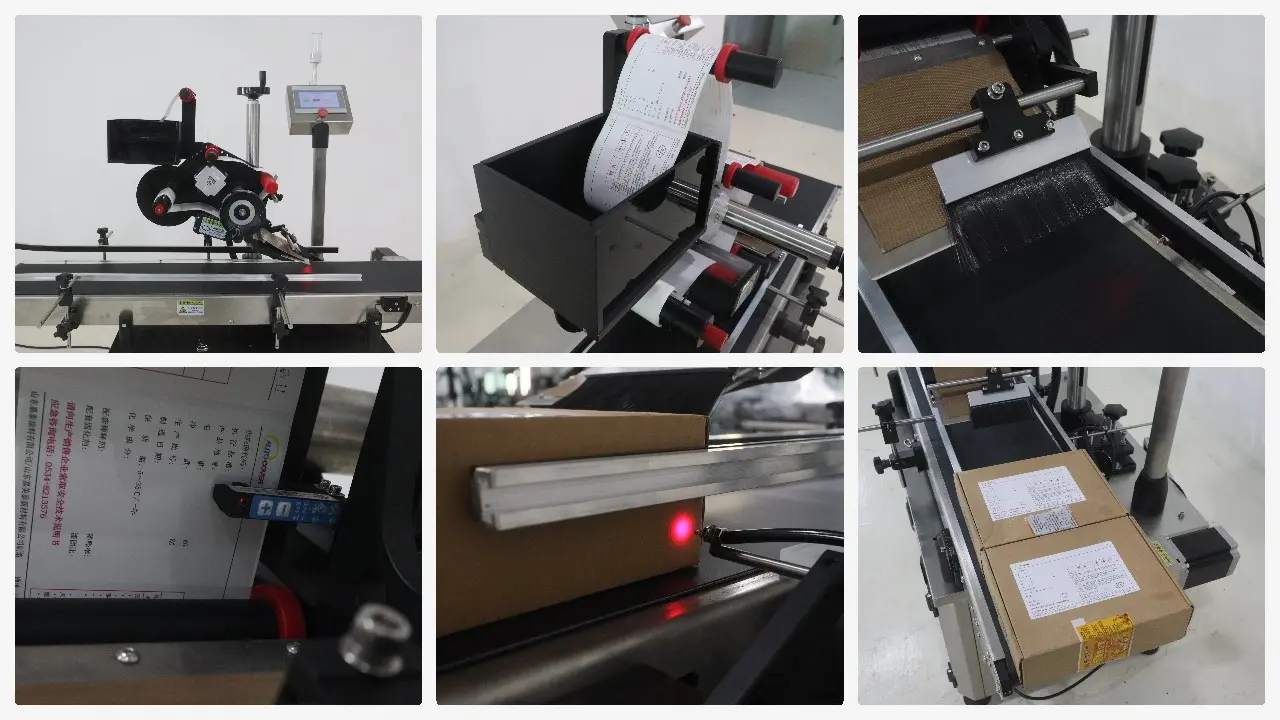

Express Bill Labeling Machine

Express bill labeling machine has a wide range of applications in express logistics, e-commerce, third-party warehousing, post office and other industries, mainly used for courier parcels on the paste courier sheet and waybill, can greatly accelerate the efficiency of labeling parcels in e-commerce service. It is a convenient, flexible and efficient labeling equipment, which is loved by users.

Gosunm express bill labeling machine is divided into desktop and vertical models, vertical express bill labeling machine stability is better, labeling speed and accuracy is higher, and can be connected to the production line to directly complete the labeling task.

Express Bill Labeling Machine

| Product Name | Automatic Vertical Express Bill Labeling Machine |

| Model | GST-113E |

| Voltage | AC220V, 50Hz, single phase |

| Labeling accuracy | ±1mm |

| Labeling Speed | 10-200pcs/min (related to the label size and product size) |

| Applicable product height | Length 10mm-500mm, Width 10-250mm, Height 1-200mm |

| Available Label Material | (Backing paper) width 10-160mm, length:15-450mm |

| Maximum label incoming size | Diameter 250mm, Inside diameter of paper roll 76mm |

| Gas consumption | No need |

| Conveyor Height | Standard height 700-800mm,other height(700-1000mm)can be customized |

| Working Environment | 10-40℃ |

| Environmental temperature | 15-85% |

| Machine Dimension | About 1600±100(L)*700±100(W)*1500±100(H)(mm) |

| Machine Gross Weight | 140kg |

| No. | Item | Brand | Origin | QTY |

| 1 | Step motor | Leadshine | China | 2 |

| 2 | Step motor drive | Leadshine | China | 2 |

| 3 | Conveyor motor | Wanshsin | China | 1 |

| 4 | Conveyor motor governor | Wanshsin | China | 1 |

| 5 | Photoelectric sensors(label) | Omron, Schneider/Panasonic | Japan/France | 1 |

| 6 | Photoelectric sensors(product) | Omron, Schneider/Panasonic | Japan/France | 1 |

| 7 | PLC | Mitsubishi/Panasonic/XINJIE/WECON | Japan | 1 |

| 8 | Earth leakage circuit breakers | Chint/schneider | China/France | 1 |

| 9 | Touch screen | WECON | China | 1 |

NOTE: the configuration may be adjusted reasonably according to the actual material delivery time, and the configuration can be revised according to customer needs

- Fully automatic labeling, can greatly improve production efficiency.

- Wide application range, suitable for a variety of sizes and types of products, can be compatible with different specifications of the label.

- Simple design, humanized user interface, very easy to operate and maintain.

- High flexibility, can quickly switch between different products and labels, especially suitable for labeling a variety of products with different specifications.

- High labeling precision, with advanced sensors and control system, it can accurately locate and label, reducing manual operation errors.