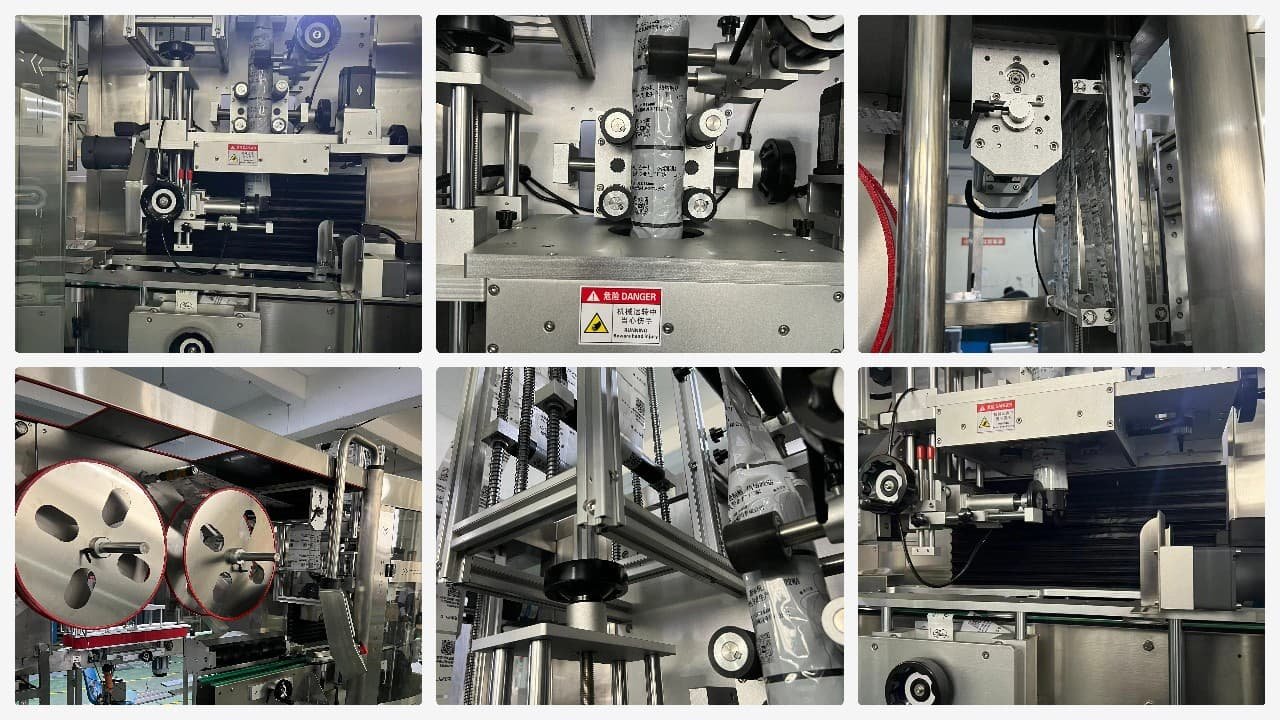

Steam Shrink Sleeve Labeling Machine

Steam shrink sleeve labeling machine is by heating pure water to produce water vapor and introduced into the space inside the shrink oven, the steam is in direct contact with the label to be shrunk, and the heat energy is transferred to the label by heat conduction. The high temperature of the steam and the pressure inside the oven cause the internal molecules of the label material to rearrange to achieve the shrinking effect. The shrunken label fits tightly onto the container, completing the labeling process.

Electric sleeve labeling machine and steam sleeve labeling machine work roughly the same principle, the difference lies in the acquisition of thermal energy in different ways, one is through the high temperature steam to transfer thermal energy, one is through the electric heating element to transfer thermal energy.

Steam Shrink Sleeve Labeling Machine

| Product Model | GL-250S |

| Production Capacity | ≥20000BPH(Elevation≤60 mm) |

| Qualified rate | ≥99.9% |

| Total line production efficiency | ≥95% (based on 24 hours) |

| Bottle Diameter | φ50mm~φ95mm, special size can be designed separately. |

| Bottle height | 30 mm -280 mm, special height can be designed separately |

| Bottle Verticality | ≤1. 0° |

| Applicable labels | PVC, PET, OPS |

| Label length | 30mm ~250mm |

| Label thickness | 0.027mm ~0.13mm |

| Label Material | PVC, PET, OPS |

| Label Clear Pitch | ≥5mm |

| Label core inner diameter | ≥4″ (76mm) |

| Label Roll Outer Diameter | ≤500mm |

| Label Tension | 220V |

| Sleeve Labeling Machine Power | 3.5KW |

| Main Machine Size | 2000X1050X2100 (L×W×H) |

| Total Machine Weight | 300 kg |